ARMS holds its 4th Consortium Meeting online

On April 24, ARMS held its fourth consortium meeting, bringing together project partners to review progress and plan future steps in advancing supercapacitor technology. The session highlighted achievements across all eight work packages (WPs) and included insights from the External Advisory Board.

WP1, led by the Institute of Solid State Physics, University of Latvia (ISSP UL), reported on the scalable synthesis of graphene-based bio-carbon materials, with promising results from recent experiments on wood-derived carbon. The team is now working on upscaling production for prototype development. KTH Royal Institute of Technology, responsible for WP2, shared progress in fabricating flexible, high-performance graphene-enhanced electrodes, with ongoing efforts to optimize their energy density and flexibility through various manufacturing techniques. WP3, managed by Tampere University (TAU), discussed improvements made via Atomic Layer Deposition (ALD), notably TiO2 coatings that enhance electrode capacitance; future work focuses on process scalability and exploring additional metal oxides.

In WP4, Innocell ApS detailed their development of safe, environmentally friendly electrolytes tailored for flexible and structural supercapacitors, with ongoing optimization and compatibility testing. WP5, led by CIDETEC Energy Storage, outlined plans for integrating these components into prototype supercapacitors; however, device fabrication has not yet commenced. The University of Southern Denmark (SDU), overseeing WP6, emphasized sustainability assessment efforts through a Safe and Sustainable by Design (SSbD) framework, aiming to minimize environmental impact and guide material choices.

Beneq, heading WP7, discussed communication strategies to increase project visibility through social media and the website, while TAU, managing WP8, highlighted the project coordination issues and revealed that the next in-person meeting will take place this October in Odense, Denmark.

The meeting served as a valuable platform for sharing progress, aligning upcoming tasks, and fostering collaboration. As the project advances, the focus remains on refining technologies within each work package and integrating them into a functional supercapacitor to meet growing energy storage demands.

ARMS project spotlight: driving sustainable energy innovations at ICAFM 2025

From March 27 to 29, the 2nd International Conference on Advanced Functional Materials (ICAFM 2025) was held in Kathmandu, Nepal. Project ARMS WP3 leader, Dr. Paul Berger from Tampere University, was a keynote speaker at the event. He presented insights into his collaborative research with colleagues Matti Mäntysalo and Donald Lupo, focusing on the synergy of their efforts and the potential applications of their findings in sustainable energy solutions.

At the conference, Dr. Berger was particularly interested in numerous presentations on supercapacitors utilizing sustainable materials, as this research area is central to the objectives of the ARMS project.

The ICAFM 2025, organized by the Nepal Materials Science Society, brought together leading researchers, academics, and industry professionals in material sciences to discuss cutting-edge advancements and innovations. The event spanned six key areas: advanced materials, energy applications, synthetic and biomedical chemistry, colloids and polymers, separation and analytical chemistry, and the role of chemistry in addressing environmental and interdisciplinary challenges.

Unveiling the inner world of the activated carbon

Activated carbon, produced by heating organic matter in the absence of oxygen and then undergoing activation, is an incredibly versatile material with applications ranging from soil improvement and water purification to energy storage. While our colleagues from the Latvian State Institute of Wood Chemistry have provided valuable insights into surface area, pore volume, and pore size distribution, we at the Institute of Solid State Physics, University of Latvia (ISSP UL) see beyond the carbon’s surface.

To understand the structure of activated carbon, Līga Grīnberga at ISSP UL employs X-ray Diffraction (XRD) and Raman Spectroscopy, revealing the hidden world of this unique material and its potential use in supercapacitor production.

To determine the order of the carbon structure, an X-ray Diffraction (XRD) analysis is performed using a Rigaku MiniFlex 600 diffractometer. This technique involves ‘shooting’ X-rays at the sample and analysing how they scatter. If sharp peaks appear in the diffraction pattern, it indicates that the biochar contains graphite-like crystalline domains. A more diffuse pattern indicates that the sample has an amorphous, disordered structure. Higher crystallinity in activated carbon can lead to better electrical conductivity, making it a more promising material for supercapacitors. However, other factors, such as porosity and surface chemistry, must also be considered to determine its true usability in energy storage applications.

XRD

diffractogram of different activated carbon samples, showing mostly amorphous

phase with some crystalline domains

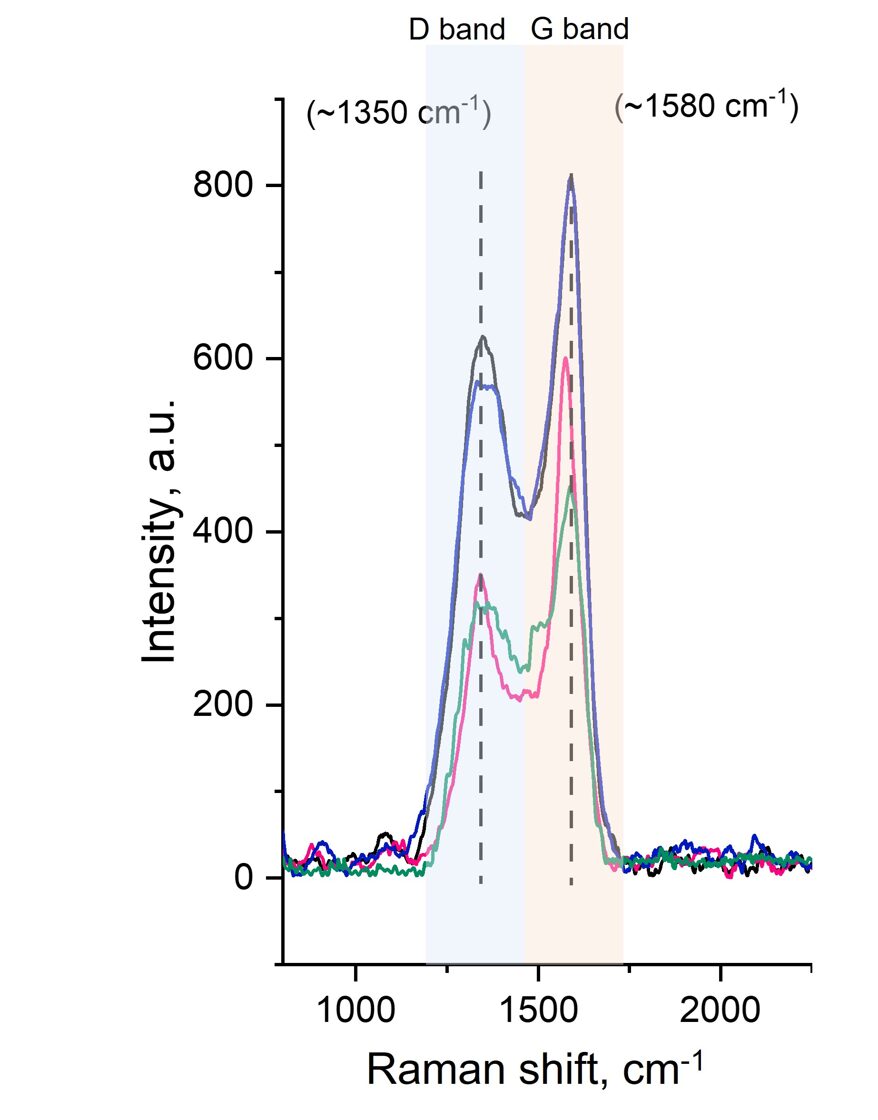

To gain deeper insight into activated carbon’s structure, Raman spectroscopy is used to analyze how a laser interacts with the sample. This technique helps distinguish between graphitic (ordered) and amorphous (disordered) carbon, with a key indicator being the D-band to G-band ratio. A higher D/G ratio suggests more disordered carbon, which is beneficial for adsorption and chemical reactivity. On the other hand, a lower D/G ratio indicates a higher graphitic content, making the activated carbon sample a better candidate for energy storage applications, such as conductive materials in batteries or supercapacitors.

Raman

spectra with indicated D and G band regions of different activated carbon

samples

In the ARMS project, these characterization techniques help to understand how different production conditions—such as temperature, feedstock, and activation methods—impact the final properties of activated carbon. So, the next time you come across a small, blackened piece of carbon, remember—it’s not just a piece of coal; it’s a material full of potential!

Project ARMS showcases innovations in sustainable electronics at LOPEC 2025

Researchers from the Tampere University (TAU) Laboratory for Future Electronics proudly represented Project ARMS during the Large-Area, Organic & Printed Electronics Convention (LOPEC) held in Munich, Germany, from February 24 to 26.

Representing the ARMS project were coordinator Prof. Matti Mäntysalo and doctoral student Remuel Isaac Vitto. Together, they promoted the project’s latest scientific publication and seized the opportunity to expand its global network, fostering connections for future collaborative research endeavors. The event was rich with exhibitions showcasing innovative applications that sparked new ideas and potential developments.

The ARMS project team had the unique opportunity to evaluate the latest advancements showcased at LOPEC, which illuminated the field from scientific, technical, and business perspectives. The exhibition featured a plethora of engaging demonstrations and cutting-edge innovations, positioning it as a pivotal event for industry stakeholders.

Annually, leading players in the field of flexible, organic, and printed electronics converge at LOPEC, bringing together companies, institutions, and researchers from around the globe to share the newest developments across various domains. This year’s event attracted 169 exhibitors from 29 countries and welcomed approximately 2,400 visitors from over 40 countries, making it an exceptional platform for TAU to present the latest research findings of Project ARMS.

TAU’s presentation emphasized key factors in developing the next generation of sustainable activated wood carbon (AWC) supercapacitors. Central to this research is the critical role of electrolyte ion kinetics and the engineered pore structures of AWC electrodes, which are vital for enhancing the performance and sustainability of energy storage solutions.

Overall, LOPEC 2025 served as an invaluable venue for knowledge exchange, collaboration, and the promotion of innovative technologies in the rapidly evolving field of organic and printed electronics.

AIMEN showcasing project ARMS at JEC World 2025

Thanks to our consortium partner, AIMEN Technology Centre, Project ARMS was featured at the JEC World 2025 exhibition on March 5-6. The project was represented by Lourdes Blanco Salgado, the lead researcher behind the development of structural supercapacitors made using the VARI process.

AIMEN showcased its latest research results in the Spain Pavilion, highlighting the centre's expertise in Advanced Composite Manufacturing. This included techniques such as thermoplastics and thermosets, Automated Fiber Placement (AFP), Resin Transfer Molding (RTM), Liquid Resin Infusion (LRI), and thermoforming. Additionally, AIMEN demonstrated its capabilities in the additive manufacturing of composites, including fused fluid fabrication (FFF), robotized large-format additive manufacturing (LFAM), and the development of filaments and pellets. The focus of these innovations spans various sectors, including automotive, aerospace, and energy.

JEC World is recognized as the premier global trade show for composite materials and their applications, and it is held annually in Paris. This year, the event attracted 1,350 exhibitors from over 40 countries and provided a networking platform for approximately 43,500 industry professionals, including decision-makers, buyers, researchers, and academics. The top five countries represented were France, Germany, Italy, Great Britain, and Spain.

In 2025, JEC World continued to offer a diverse array of exhibitors from different regions, fostering connections between composites companies and potential buyers. The event will showcase innovative solutions and advancements across all markets within the global composites sector, driving growth and collaboration in this dynamic field.

Read more about JEC World 2025: https://www.jec-world.events/

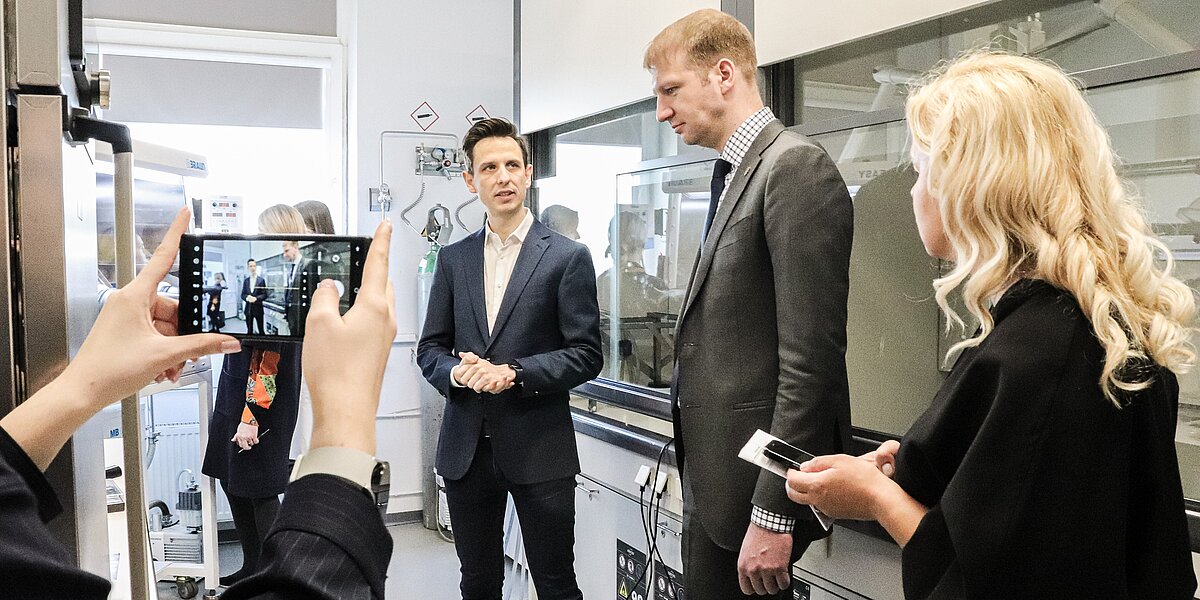

The Minister of Climate and Energy of Latvia explores energy storage research at ARMS partner - ISSP UL

On February 19, the Institute of Solid State Physics, University of Latvia (ISSP UL) had the honor of hosting distinguished guests, including Kaspars Melnis, the Minister of Climate and Energy, along with Krista Garkalne, head of the minister’s office, and Sāra Šabazova, senior expert in strategic communication and public engagement. They were warmly welcomed by the ISSP UL leadership and Gints Kučinskis, who heads the ISSP UL’s Energy Materials Laboratory and leads the ARMS WP1. This visit was part of the Ministry's initiative to gain insights into the latest advancements in energy storage technologies and materials science, evaluate how the research at ISSP UL can inform and shape future climate and energy policies in Latvia, and strengthen relationships between government and research institutions, fostering a collaborative approach to addressing energy challenges.

The day started with a presentation highlighting ISSP UL’s research initiatives and notable achievements. After that, the guests took a tour of the laboratory facilities, including the Energy Materials Laboratory, where the ARMS project’s WP1 is underway. At the lab, they delved into ongoing research to enhance energy storage technologies, focusing on developing materials for lithium-ion (Li-ion) and sodium-ion (Na-ion) batteries, supercapacitors, and advancements in hydrogen production and storage. The delegation learned how innovative work at the Energy Materials Laboratory harnesses advanced material science and engineering to boost the efficiency and effectiveness of energy storage systems.

Following the lab tour, the conversation turned to future energy challenges, covering topics such as the evolution of energy storage technologies, the promise of hydrogen energy, and the role of nuclear technology in strengthening Europe’s energy independence. Given its position as the primary national authority on climate and energy policies, the Ministry of Climate and Energy of Latvia is essential in these discussions, underscoring the need for collaboration in addressing global energy issues.

Inside out: the crucial role of sorptometry in the study of activated carbons

Activated carbon is widely used for various applications, such as water purification, air filtration, and chemical separation, primarily due to its high surface area and porous structure. However, it is important to understand what happens inside these extremely porous materials, since light cannot go there, and other methods will show us mostly the surface of these minuscule carbon particles.

One of the main aspects of researchers at the Latvian State Institute of Wood Chemistry (LSIWC), Aleksandrs Volperts, and Ance Plavniece, is the testing of the newly synthesized carbon materials using specially designed sorption of nitrogen gas method at the frigid temperature of 77K, which is almost -200 oC! One of the most important aspects of sorptometry in studying activated carbons is its ability to provide insights into the material's surface area, pore volume, and pore size distribution. By conducting sorption experiments with gases or liquids, researchers can determine the extent to which activated carbon can adsorb different substances. These measurements reveal the adsorption capacity, which is critical for assessing the material's efficiency in various applications, from removing impurities in the water to filtering toxic gases from the air.

This method is the most important and informative for the given tasks in the framework of the ARMS project since the application of sorptometry of activated carbon is highly relevant to the development of supercapacitors. The performance of supercapacitors, which rely on activated carbon as the electrode material, is closely linked to the material's specific surface area and pore structure. Sorption measurements help optimize the properties of activated carbon to improve energy storage efficiency, cycle stability, and power density in supercapacitors. By understanding the adsorption characteristics at the molecular level, researchers can design activated carbons with better performance, making sorptometry essential for advancing energy storage technologies.

Sorptometry aids in understanding the interaction between adsorbates (substances being adsorbed) and the surface of activated carbon. This includes factors like the type of adsorption mechanism, whether physical or chemical and the influence of temperature and pressure on the adsorption process. Sorption isotherms are commonly derived from sorption data to explain these interactions more quantitatively, and various theories are applied to derive the required characteristics.

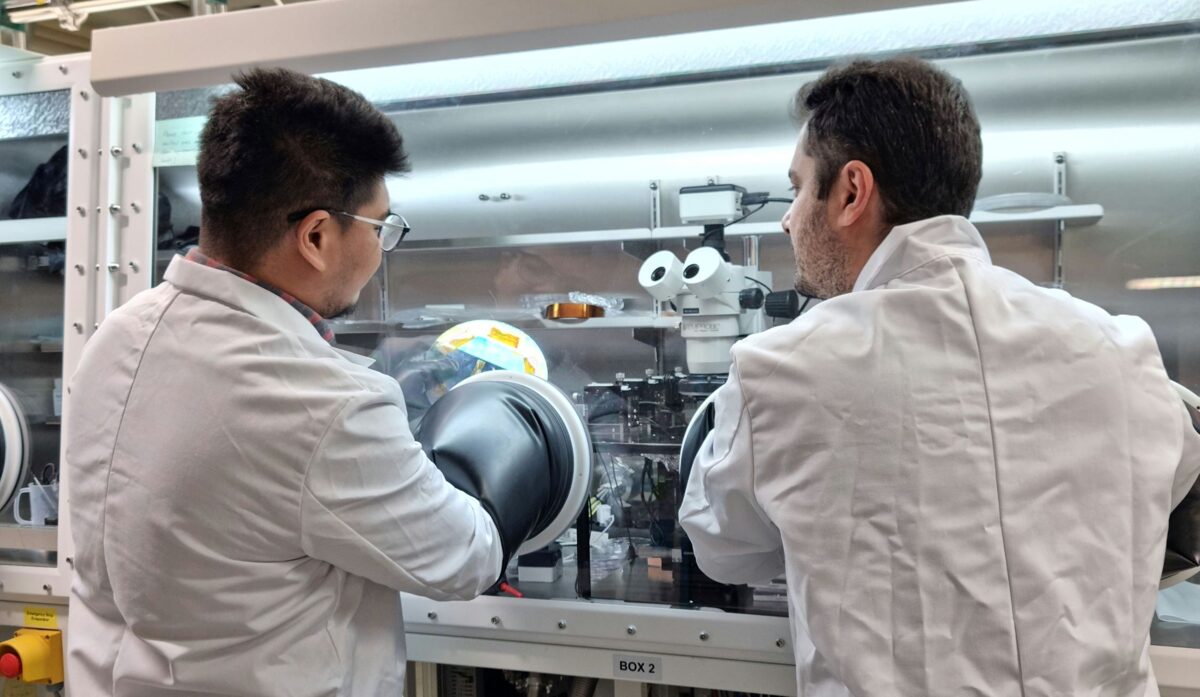

Atomic layer deposition at Tampere University: boosting supercapacitor performance

At Tampere University (TAU), cutting-edge nanotechnology is at the heart of our contribution to the ARMS project. Using Atomic Layer Deposition (ALD), we decorate supercapacitor electrodes at the nanometer scale. This precise technique enhances the energy density of the final supercapacitor, pushing the boundaries of energy storage technology.

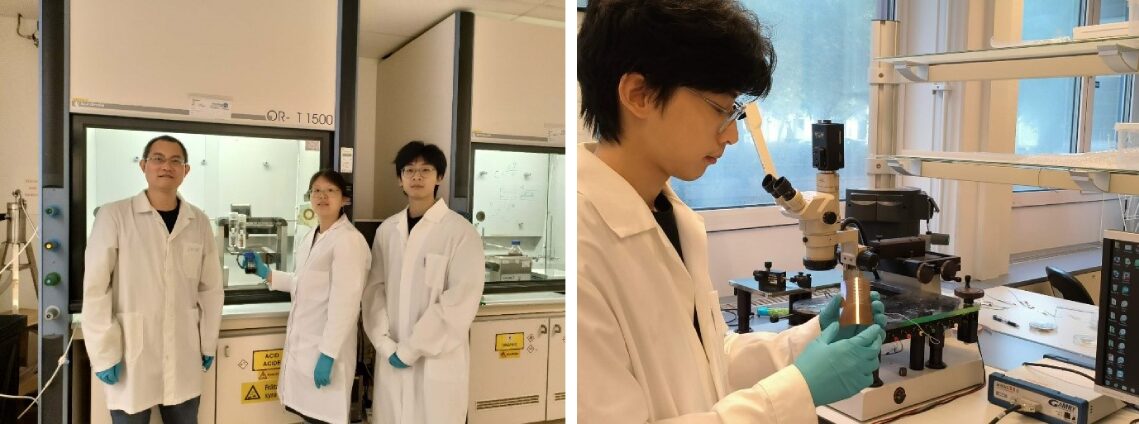

Recently, our team captured a moment in the lab featuring Hamed (a post-doctoral researcher) and Remuel (a doctoral researcher) working with the glove box. A glove box is a sealed container designed to allow researchers to handle sensitive materials in a controlled atmosphere, free from contaminants like moisture or oxygen. Inside this glove box, the ALD chamber is located, providing a controlled environment for the deposition process. In the photo, Hamed and Remuel are carefully placing the electrodes into the ALD chamber, ensuring the highest level of precision for the nanometer-scale electrode decoration.

The dedication and teamwork behind this innovative research highlight TAU’s vital role in advancing the ARMS project. Stay tuned for more updates as we continue exploring new frontiers in energy storage with flexible and structural supercapacitors!

Powering tomorrow: the role of supercapacitors in green energy solutions

In a recent interview on the Latvian National Radio program (LR1) "Zināmais nezināmajā" (Known in the Unknown), project ARMS WP1 leader and the head of the Energy Materials Laboratory (Institute of Solid State Physics, University of Latvia), Gints Kučinskis, together with his colleague, Gunārs Bajārs, focused on the challenges associated with lithium batteries, while also addressing the potential of supercapacitors.

With increasing environmental concerns over lithium extraction, which is characterized by excessive water consumption and soil degradation, the need for sustainable energy solutions is not just a future goal, but an urgent necessity. As the demand for lithium faces supply limitations, researchers are actively exploring alternatives like supercapacitors and sodium-ion technology.

Gunārs Bajārs underscored the critical need for diversifying energy sources, particularly in light of the limited lithium availability in Europe and the geopolitical factors impacting supply. His statement, "It’s not that we will need another element tomorrow, but we have to think about it," serves as a reminder of the necessity to explore and invest in alternative energy solutions.

The researchers also discussed advancements in supercapacitors developed in the ARMS project, focusing on using graphene to enhance energy density and sustainability and aiming for high performance while minimizing environmental impact. Such supercapacitors can provide rapid charge and discharge capabilities, making them suitable for renewable energy systems, electric vehicles, and portable electronics applications.

As discussions on the implications of lithium dependency continue, the focus on supercapacitors and sodium-ion technology reflects a commitment to finding sustainable and stable energy alternatives.

"Zināmais nezināmajā" is a popular science radio magazine that delves into various scientific fields, including nature, ecology, and history, while highlighting significant scientific achievements and the contributions of notable researchers, particularly focusing on the accomplishments of Latvian scientists both locally and globally.

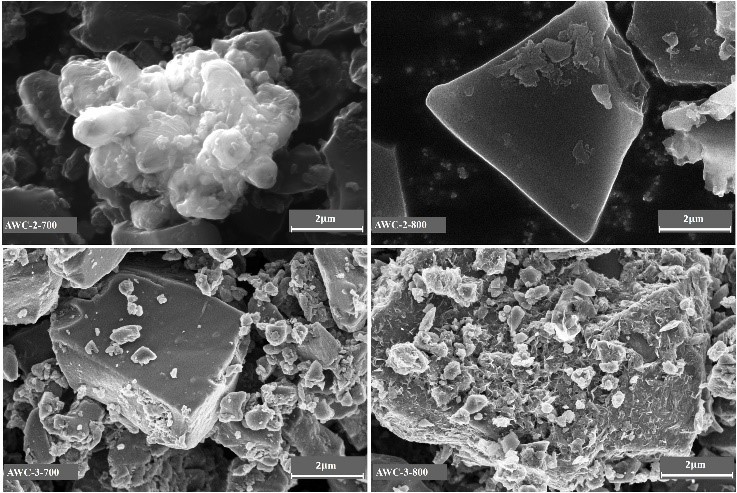

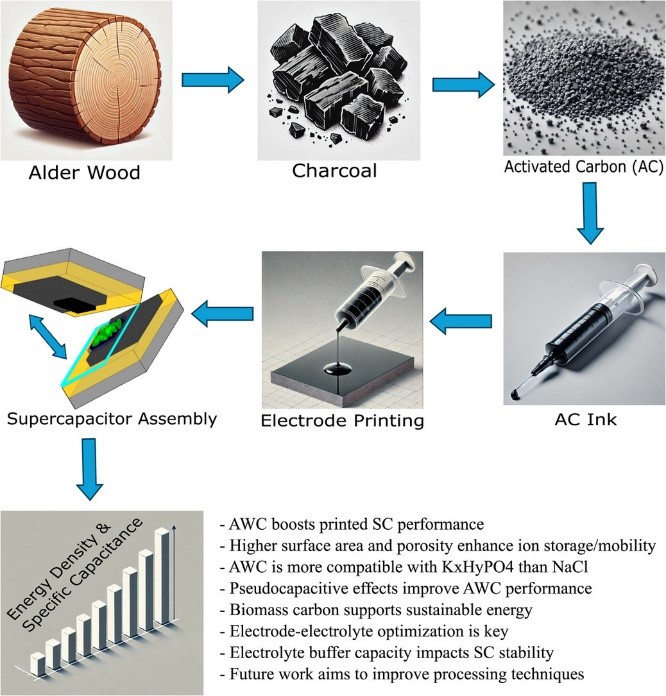

First publication from the ARMS project: sustainable wood carbon for next-generation energy storage

SEM images of AWC samples

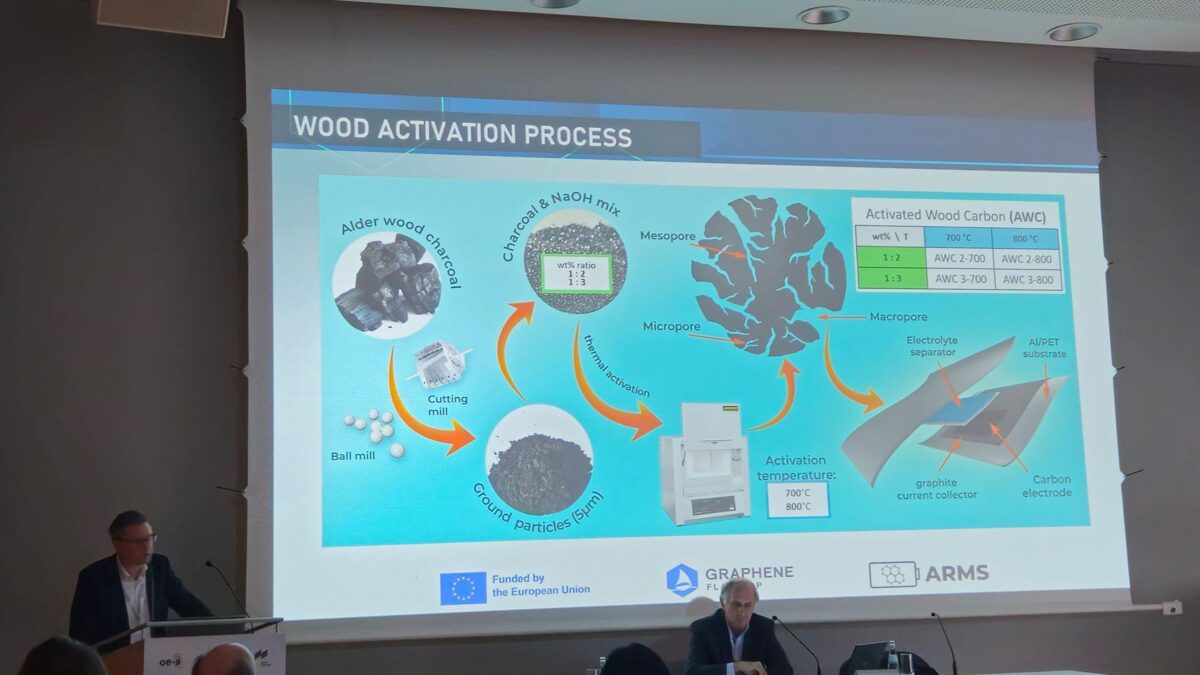

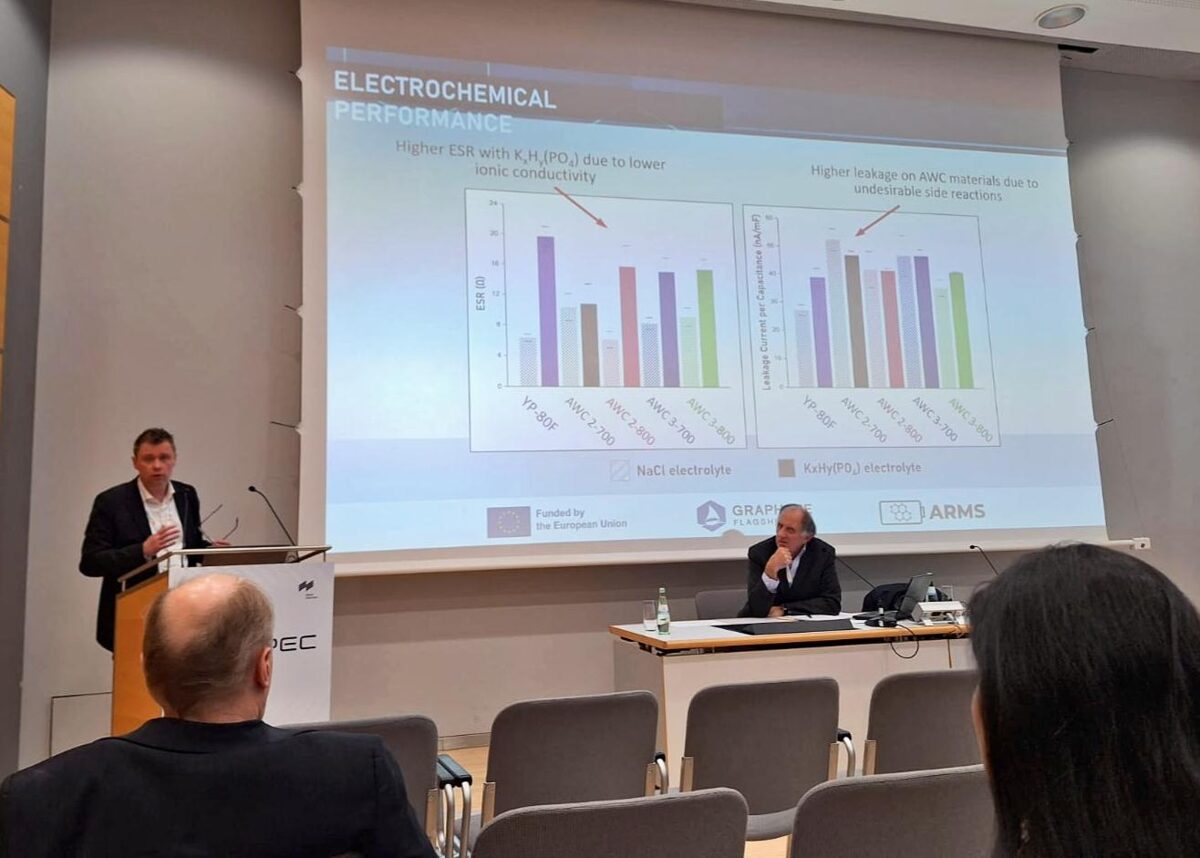

The ARMS project's first scientific publication, “Enhancing Specific Capacitance and Energy Density in Printed Supercapacitors: The Role of Activated Wood Carbon and Electrolyte Dynamics,” was published in the open-access journal Carbon Trends. The publication explores the potential of Activated Wood Carbon (AWC) – a sustainable and innovative material – for use in printed supercapacitors. The team of researchers from Tampere University (Finland), the Latvian State Institute of Wood Chemistry (Latvia), InnoCell ApS (Denmark), and the Institute of Solid State Physics, University of Latvia (Latvia) investigated the impact of AWC's unique structural properties on the performance of these energy storage devices. They also examined how different electrolytes influence the overall energy storage capabilities.

The study involved comprehensive analysis using techniques such as sorptometry, Raman spectroscopy, X-ray diffraction, and electrochemical assessments. These analyses provided crucial insights into the relationship between AWC's structure and its electrochemical behavior. The researchers compared the performance of supercapacitors using AWC to those using a commercially available benchmark material.

Remarkably, the results demonstrated a significant enhancement in both specific capacitance and energy density when using AWC. In fact, the supercapacitors using AWC showed improvements of up to 93% in specific capacitance and 90% in energy density compared to the benchmark material at specific operating voltages. This significant performance improvement is attributed to AWC's superior surface area and porous structure, which offers abundant sites for ion storage and facilitates efficient ion transport.

Furthermore, the choice of electrolyte played a critical role in determining the overall performance. The study compared two different aqueous electrolytes—demonstrating that the KxHyPO4 electrolyte yielded superior results compared to NaCl. This difference underscores the importance of carefully selecting electrolytes to optimize the performance of supercapacitors.

This research showcases the promise of AWC as a sustainable and high-performing electrode material for printed supercapacitors. The findings represent a significant step towards developing environmentally friendly and efficient energy storage solutions for a more sustainable future.

Read the full paper here.

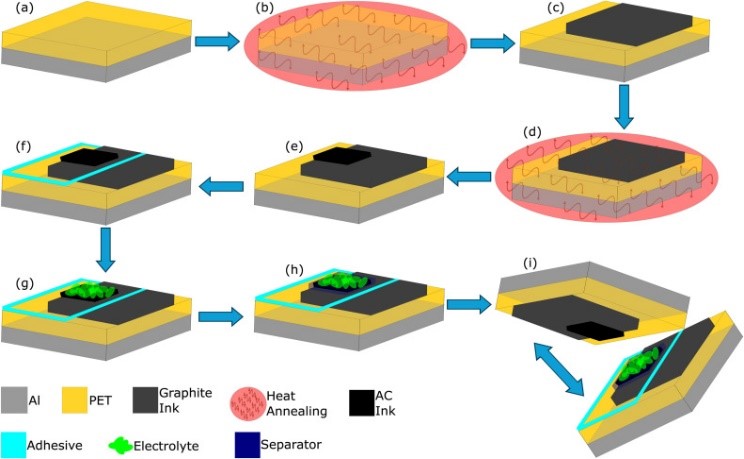

Graphical abstract of the publication

Supercapacitor fabrication steps

Advancing sustainable innovation: the University of Southern Denmark's role in the ARMS project

The University of Southern Denmark (SDU) is a relatively young and fast-growing Danish university (started in 1966). It consists of five faculties that educate just under 30,000 students, and five campuses, the largest of which is in Odense, on the island of Funen. The Faculty of Engineering, affiliated with ARMS, has gained a reputation for cutting-edge research, especially in robotics, and has generated many startups.

The team at SDU involved in the ARMS project consists of Associate Professor Ciprian Cimpan and Postdoctoral Fellow Suiting Ding. The two are part of SDU Life Cycle Engineering, a research section focusing on advancing sustainable solutions through life cycle thinking. The research group specializes in life cycle assessment (LCA), environmental management, and eco-design. They work on evaluating environmental impacts across the entire lifecycle of products, systems, and processes, contributing to sustainable innovation in industries such as energy, materials, and waste management.

Showcasing project ARMS at the International Research Funding Days

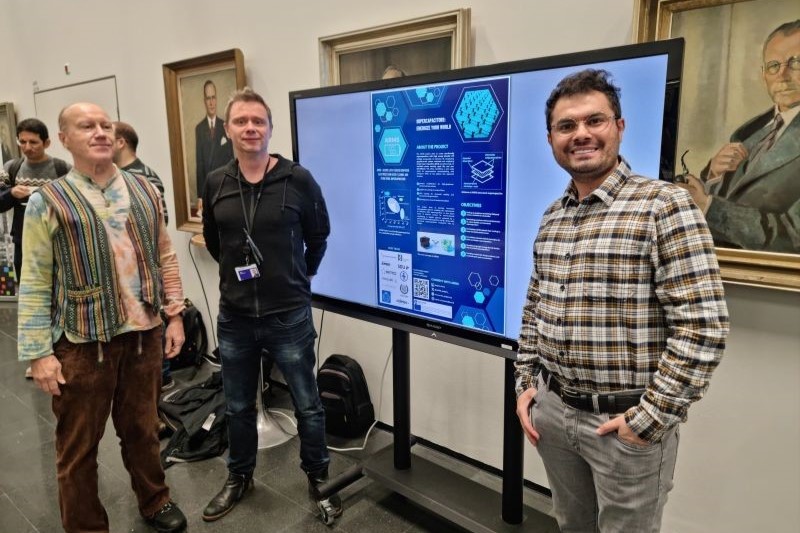

On December 5th, the project coordinator’s team at Tampere University had the exciting opportunity to present the EU-funded ARMS project at the "International Research Funding Days" organized by Tampere University (TAU). The event gathered all TAU-coordinated projects for a Poster Session, creating an environment rich with insights, knowledge sharing, and networking opportunities.

The event showcased innovative research conducted across various disciplines. Connecting with other Horizon Europe projects and exchanging ideas with fellow researchers was particularly inspiring. This exchange broadened our perspective and sparked new ideas for future research directions.

In addition to presenting the ARMS project, the team consisting of Matti Mäntysalo (project coordinator) and Hamed Pourkheirollah (post-doc researcher and ARMS technical manager) took the valuable opportunity to strengthen collaboration with the TAU pre-award team. Their support and insights have been instrumental in advancing ARMS goals. Engaging with them at the event helped solidify our ongoing partnership and explore new avenues for collaboration.

With over 100 attendees, the event was a resounding success, serving as a wonderful platform for expanding networks and highlighting the cutting-edge research within the Tampere University community. The diverse presentations underscored the importance of interdisciplinary collaboration in driving innovation and addressing complex global challenges.

Looking ahead, we are eager to participate in more such opportunities that enable us to connect, collaborate, and contribute to the future of research. The event reaffirmed our commitment to fostering a collaborative research environment that thrives on shared knowledge and mutual support.

Project ARMS extends its heartfelt thanks to Tampere University for organizing this event and all participants for making it a memorable experience. We are excited to continue building on these connections and exploring new possibilities for the ARMS project.

ARMS consortium partners gather for the Consortium Meeting in Riga

On November 5-6, all consortium partners and members of the External Advisory Board convened for the 3rd Consortium Meeting at the Institute of Solid State Physics, University of Latvia. This event marked a significant milestone in the ARMS project, bringing together experts dedicated to advancing energy storage technologies.

The ARMS project aims to develop and integrate advanced materials and processes for producing eco-friendly supercapacitors. By enhancing the performance and sustainability of energy storage devices, the project seeks to contribute to breakthroughs in materials engineering and innovative energy solutions. These objectives are essential in addressing global energy challenges and promoting environmentally friendly technologies.

To facilitate our work, the project is organized into eight comprehensive work packages, each led by dedicated partners from the ARMS consortium:

- WP 1 Synthesis of Raw Graphene-Containing Carbon-Based Electrode Materials (led by the Institute of Solid State Physics, University of Latvia) focuses on developing new materials that can improve the efficiency of supercapacitors.

- WP 2 Electrode Fabrication (KTH) – working on creating electrodes that maximize performance and longevity.

- WP 3 Electrode Booster (ALD) – explores advanced techniques to enhance electrode properties (Tampere University).

- WP 4 Electrolytes (led by InnoCell) – working on formulating electrolytes that complement the new materials and improve overall device performance.

- WP 5 Supercapacitor Device Integration and Demonstration (CIDETEC) focuses on integrating the various components into functional supercapacitor devices and demonstrating their capabilities.

- WP 6 Sustainability Assessment (led by the University of Southern Denmark) evaluates the environmental impact of the materials and processes developed throughout the project.

- WP 7 Dissemination, Exploitation, and Communication (Beneq) – effectively communicates the findings and progress of the project and ensures that results reach relevant stakeholders and the public.

- WP8 Project Management and Coordination (Tampere University) oversees the overall organization and coordination of project activities to ensure smooth progress.

During the Riga meeting, partners had the opportunity to present their progress and findings from the project's first year. The discussions surrounding the results of the initial four work packages were particularly engaging as participants evaluated their achievements and strategized for future collaborations on technical and research tasks. Insights and feedback from the External Advisory Board members, Dr. Martin Krebbs (founder of PrintaBattery and member of the Organic and Printed Electronics Association) and Dr. Jakob Heier (the Swiss Federal Laboratories for Materials Science and Technology (Empa)), provided valuable perspectives that will guide our next steps.

At the end of the first day, project partners enjoyed a guided tour of the Institute of Solid State Physics laboratories. This visit allowed the ARMS consortium members to witness firsthand the state-of-the-art equipment and research facilities available at ISSP UL, enhancing their understanding of the resources utilized in WP1 research.

Following a busy and productive first day, all eleven consortium partners gathered for a convivial dinner, where discussions about the project’s research and development continued in a more informal setting. This gathering fostered collaboration and strengthened the relationships among team members.

We extend our heartfelt thanks to ISSP UL and the city of Riga for their warm hospitality during our stay. We look forward to continuing our work together and gathering again next year in Denmark, where we will further our mission to innovate in eco-friendly energy storage solutions!

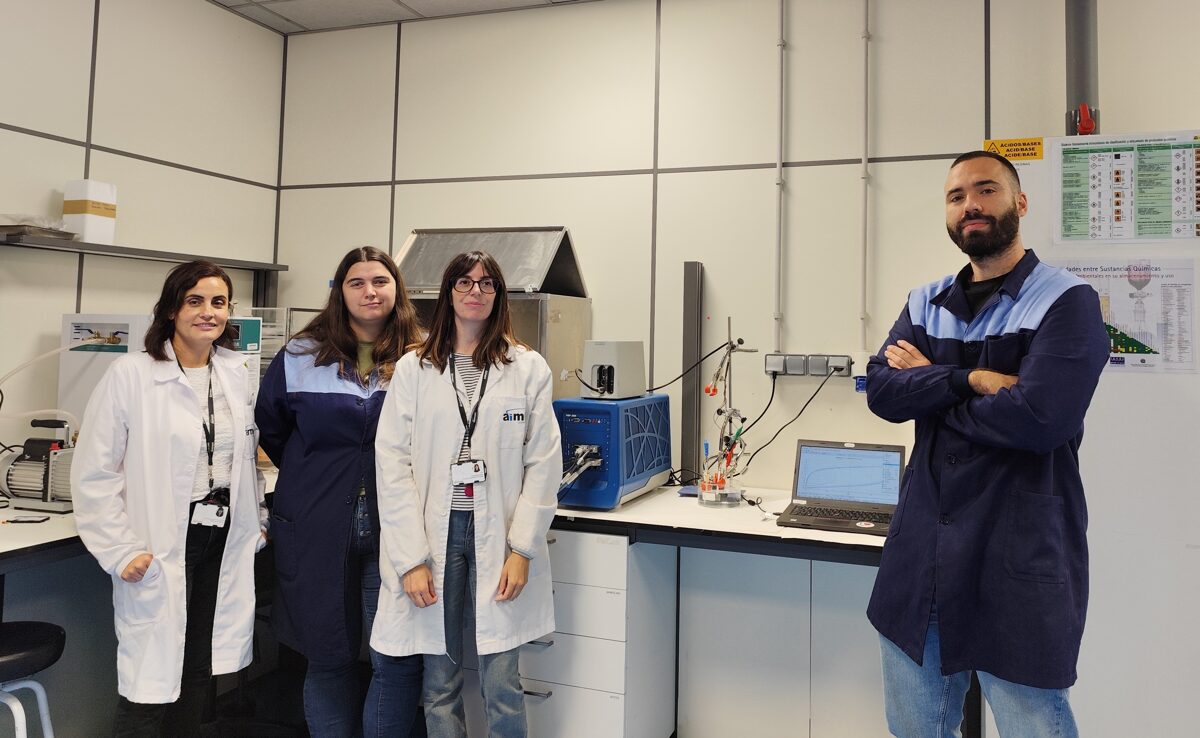

ARMS project: Introducing AIMEN’s capabilities, role in the project, and research team

AIMEN Technology Centre, with more than 57 years of history, is currently a national and European benchmark in research, development, and technological innovation in the areas of advanced manufacturing and laser manufacturing, digital technologies for manufacturing, smart materials, smart systems, and recycling; as well as in the provision of differentiating technological services to the industry in the areas of manufacturing with advanced joining technologies, robotics and process digitization, a flexible cross-engineering service highly specialized in welding, corrosion, equipment calculation, product simulation and material tests. AIMEN conducts R&D&I activities and offers technological services for various sectors, including mobility, construction, aerospace, energy, and chemistry, among others. Currently, AIMEN manages 78 EU R&D projects, 20 of which it coordinates.

As part of the ARMS project, AIMEN is concentrating on the desizing and activation of carbon fibre for graphene coating to maximize the capacitance of electrodes. Additionally, the project involves studying the rheology of an electrolyte system compatible with epoxy resin and developing structural supercapacitors through vacuum resin infusion, which will be incorporated into a drone. Furthermore, AIMEN will conduct electrochemical analyses to determine the energy density and power density of the developed structural supercapacitors while also evaluating their mechanical properties.

To date, AIMEN leads task 2.2, in which it collaborates with KTH and Chalmers University, which is responsible for the graphene coating. AIMEN provides the desired carbon fibre and conducts the electrochemical characterization of the coated graphene carbon fibre electrodes (WP2). Additionally, cooperation with Innocell has focused on optimising an electrolyte system for structural supercapacitors (WP4). The rheology tests will provide valuable information for finding a suitable resin/electrolyte system, as well as key parameters of the curing process (curing temperature and time), which will serve as inputs for WP5, focused on the development of structural composite laminates/supercapacitors.

The team at AIMEN involved in the ARMS project consists of four members: Cintia Mateo Mateo, Ignacio Ezpeleta Vázquez-Redonet, Marisol Rivas Caramés, and Lourdes Blanco Salgado.

AIMEN's expertise includes electrochemistry (Potentiostats/Galvanostats, software analysis, and general electrochemical instrumentation), analysis techniques (DSC, TGA, SEM, SEM-EDS), rheology, and mechanical testing (tensile, compression, bending, and fatigue tests), as well as electrical characterization. Additionally, AIMEN has competencies in the development of out-of-autoclave composites, including vacuum infusion setups, degassing systems, ovens, molds, and more.

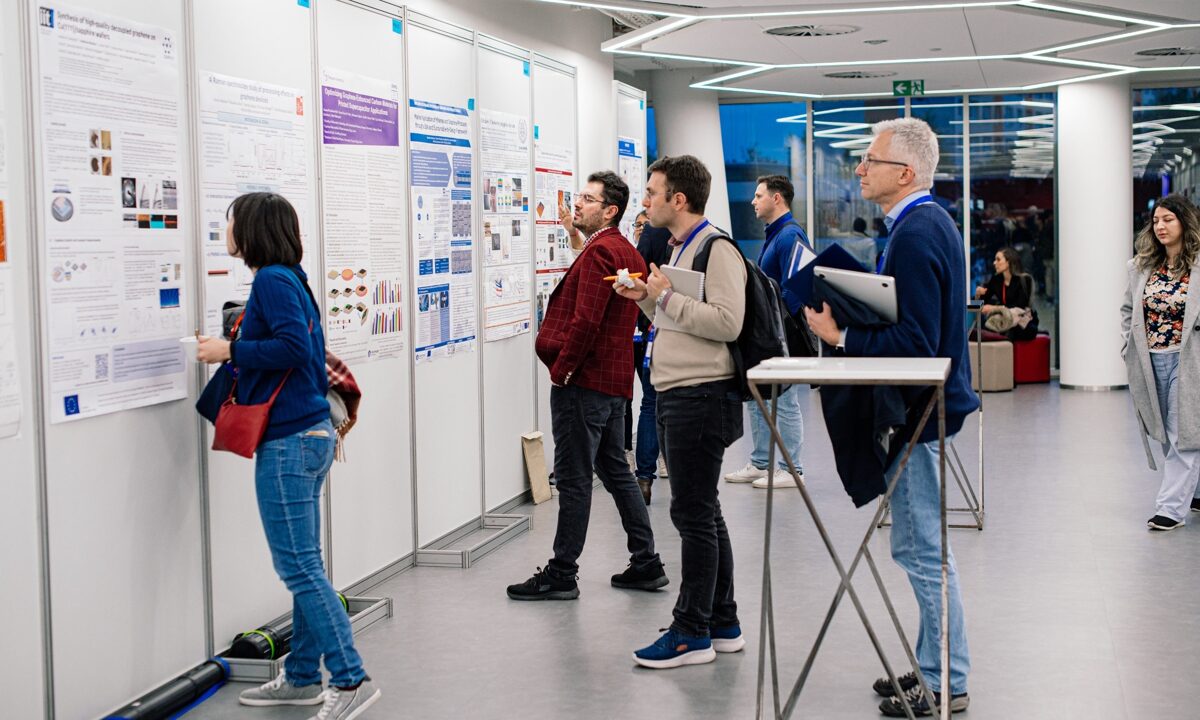

ARMS Project at Graphene Week 2024

The 19th edition of Europe’s leading Graphene and 2D materials conference, “Graphene Week 2024,” took place in Prague, the Czech Republic, October 14 – 18, 2024. This annual event gathered graphene experts and Graphene Flagship associated projects. Our project was represented by its technical project manager and post-doc researcher, Hamed Pourkheirollah from Tampere University and Associate Professor Jinhua Sun from Chalmers University.

Throughout Graphene Week 2024, Dr. Pourkheirollah participated in various Graphene Flagship meetings, including road mapping, coordination board discussions, the project managers meeting, and the annual general meeting. These sessions offered an excellent platform to discuss ARMS’ contributions and align with Flagship's strategic goals.

The ARMS project was well-represented with its pod in the Graphene Flagship Hall, where Hamed and Jinhua introduced the ARMS project to the people who were eager to know more about the research performed within our consortium. Discussions with researchers and Graphene Flagship sibling project representatives fostered valuable connections and explored potential collaborations.

On October 16, both Hamed and Jinhua gave their talks at the workshop “Integrating Graphene Innovations: From Smart Textiles to High-Performance Energy Storage,” which was co-hosted with the Graphene Flagship sibling project, GRAPHERGIA. In the workshop, project ARMS representatives provided insights into ARMS’ technical advancements. The workshop also initiated several interesting discussions with international researchers.

Dr. Hamed Pourkheirollah also participated in the Graphene Week 2024 poster session, where he showcased a technical poster detailing ARMS’ recent innovation, sparking interest and conversation among attendees. Furthermore, the Graphene Flagship arranged a professional video interview for ARMS, where Hamed discussed the project’s objectives, recent developments, and future aspirations.

Whereas Jinhua Sun had the valuable opportunity to explore the cutting-edge 2D materials research labs at the University of Chemistry and Technology in Prague, gaining insight into the innovative work being conducted in this rapidly evolving field.

The Graphene Flagship 2024 proved to be an enriching experience, allowing Hamed and Jinhua to exchange knowledge with experts across various fields, discuss ARMS’ breakthroughs, connect with peers from other flagship-associated projects, and build their network. The event was a significant opportunity for the ARMS project to highlight its advancements on a global stage.

Environmentally friendly supercapacitors with an aqueous hybrid electrolyte developed by Danish company InnoCell

InnoCell specializes in the development and manufacture of new types of supercapacitors. One of the company’s primary objectives is to create supercapacitors that are as sustainable, safe, and environmentally friendly as possible.

The ARMS project plays a significant role in achieving these goals by fostering collaboration among many of Europe’s leading experts in relevant fields, providing InnoCell with a unique opportunity to improve its core technologies.

Within the project, InnoCell is developing its bio-curved graphene electrode material alongside other high-performance bio-based electrode materials. These materials undergo further enhancement through Atomic Layer Deposition (ALD) treatment to improve capacitance and electrochemical stability. In addition to electrode material development, the interaction between the electrolyte and electrode is studied, leading to the optimization of electrolytes based on InnoCell’s patented aqueous hybrid electrolyte technology.

The final materials are demonstrated in both traditional supercapacitors with pouch cell encapsulation and novel approaches such as flexible and structural supercapacitors.

ARMS unlocking innovation at GRAPHENE WEEK 2024 – Europe’s leading conference on graphene and 2D materials

The 19th edition of Europe’s leading Graphene and 2D materials conference, “Graphene Week 2024,” will take place in the Cubex Center in Prague, the Czech Republic, October 14 – 18, 2024. Project ARMS will participate in this important event, standing at the forefront of cutting-edge research, innovation, diversity, and technology. Our project representatives will not just co-host a workshop with our colleagues from the GRAPHERGIA project, but they will also present project ARMS at the Graphene Flagship Hall with our sibling projects.

The highlight of our participation at the Graphene Week 2024 is Workshop #2, “Integrating Graphene Innovations: From Smart Textiles to High-Performance Energy Storage,” co-hosted with our sibling project GRAPHERGIA. The workshop will be held on Wednesday, October 16, from 11:15 to 13:15, where our technical project manager and post-doc researcher, Dr. Hamed Pourkheirollah (Tampere University), and Associate Professor Jinhua Sun (Chalmers University of Technology) will talk about graphene functionalization and energy-related, namely, supercapacitor, applications.

In the workshop, participants will discover how graphene revolutionizes industries, exploring innovative graphene production methods and its diverse applications, including smart textiles and advanced energy storage solutions.

Project ARMS will also be presented in the Graphene Flagship Hall, highlighting the initiative and its 14 projects. The Graphene Flagship booth will greet visitors as they come up the stairs into the venue and will highlight the full initiative and how it works. As the visitors proceed toward the auditoriums, they will walk by individual project pods where you will find project ARMS, represented either by our technical project manager, Dr. Hamed Pourkheirollah, or Associate Professor Jinhua Sun.

You will find project ARMS there at the following times:

- Monday, October 14: 15:45 -16:15

- Tuesday, October 15: 10:45 - 11:15, 13:15 - 14:15, 16:15 - 16:45

- Wednesday, October 16: 10:45 - 11:15, 13:15 - 14:15, 16:15 - 16:45

- Thursday, October 17: 10:45 - 11:15, 13:15 - 14:15, 16:15 - 16:45

More about the Graphene Week 2024

Supported by the European Commission, Graphene Week 2024 stands at the forefront of cutting-edge research, innovation, and technology. As Europe’s leading and longest-running graphene conference, it unites over 500 international experts and students to discuss key topics concerning graphene and 2D materials. In 2024, the program welcomes over 200 speakers, an Innovation Forum, an Exhibition, and dedicated sessions on diversity, early career development, EC future opportunities, and 2D materials for the future. Join us for the 19th edition of Graphene Week 2024 in Prague, and let’s turn wonder into action!

Innovating energy storage: graphene-enhanced micro-flexible and structural supercapacitor electrodes at KTH Royal Institute of Technology

The Printed Electronics group at KTH has extensive experience in developing eco-friendly conductive inks using carbon-based materials, particularly graphene and other 2D materials. These inks are tailored for various manufacturing processes, such as inkjet printing, 3D printing, airbrush spraying, and supersonic spraying, and serve a range of industrial applications, including supercapacitors, thermally conductive coatings for electronics cooling, and conductive wear-resistant coatings for electrification. KTH is also exploring innovative self-charging energy systems that combine energy harvesters (triboelectric nanogenerators) with energy storage devices (microsupercapacitors) to capture and store energy from the environment.

In ARMS, KTH leads Work Package 2 (WP2), focusing on the fabrication of graphene-enabled binder-free electrodes for micro-flexible and structural supercapacitors. The primary responsibility under WP2 is the development of supercapacitor electrodes compatible with atomic layer deposition (ALD) processes in WP3. KTH has been using the bio-derived activated carbon materials and graphene supplied by other partners to formulate proper inks and fabricate graphene-enhanced binder-free carbon electrodes on both flexible substrates and carbon fibres.

The ARMS project team at KTH is led by Assoc. Prof. Jiantong Li, mainly with the support of Dr. Yingchun Su and PhD student Yujie Fu. Currently, we have developed processes to fabricate binder-free carbon electrodes on flexible (Kapton) substrates and carbon fibers with thermal stability higher than 300 oC. The good thermal stability will provide more flexibility for WP3 in selecting compatible materials for the ALD processes. Based on the feedback from partners, we are developing appropriate processes to improve the adhesion property of the binder-free electrodes.

Advancing energy storage: the role of the ISSP UL in the ARMS project

The Institute of Solid State Physics, University of Latvia (ISSP UL) is an internationally recognized leader in materials science, specializing in solid-state physics, materials science, and nanotechnology. The ISSP UL fosters interdisciplinary collaboration among physicists, chemists, and engineers, all while being equipped with state-of-the-art laboratories and facilities that drive innovative research and the development of new materials. Moreover, ISSP UL is committed to educating future scientists and facilitating partnerships with industry, thereby advancing technology and knowledge in solid-state physics at both local and international levels.

Central to implementing the ARMS project at ISSP UL is the Energy Materials Laboratory, which focuses on advancing knowledge and technologies in lithium and sodium batteries, as well as supercapacitors. This work addresses pressing issues related to climate neutrality, energy provision, and sustainable solutions.

ISSP UL leads Work Package 1 (WP1), which is dedicated to synthesizing raw graphene-containing carbon-based electrode materials. In addition to research endeavors, the institute oversees communication and dissemination activities under WP7, ensuring that project developments are effectively shared.

The dedicated team at ISSP UL working on the ARMS project consists of five members. Under the leadership of Dr. Gints Kučinskis, the Energy Materials Laboratory drives the scientific tasks within WP1. The team includes researcher and Ph.D. student Dāvis Kalniņš, research assistant Roberts Palmbahs, and structural characterization expert Dr. Līga Grīnberga. Inese Jansone, a specialist in scientific communication from the ISSP UL Development Department, manages ARMS project communication and dissemination efforts.

ISSP UL’s expertise encompasses the electrochemical and structural characterization of supercapacitor materials, supported by advanced resources such as an electrochemistry lab with over 75 test channels and equipment for ALD, SEM, XRD, XPS, TEM, and Raman spectroscopy. The research within the ARMS project is focused on developing graphene-containing carbon-based electrode materials for efficient supercapacitors. The ISSP UL’s team is committed to creating innovative carbon materials that will be further transformed into high-performance electrodes, ultimately integrated into the ARMS supercapacitor.

Collaboration with INNOCELL and the Latvian State Institute of Wood Chemistry allows ISSP UL’s team to analyze the structure and electrochemical properties of electrode materials in partnership with researchers from Tampere University. WP1 actively analyzes samples and holds meetings with other ARMS partners every three weeks to discuss project progress. WP1 activity within the project spans three years. Currently, almost one-third of the tasks are complete.

To date, we have successfully developed synthesis techniques in collaboration with our partners and established the materials needed for the project. WP1’s goal, along with our colleagues', is to optimize and improve the materials further, aiming to produce them in larger quantities by the third year.

Project ARMS co-hosted a workshop empowering innovation at the IEEE FLEPS 2024 Conference in Tampere

On June 30, project ARMS co-hosted a workshop exploring energy-autonomous wearable electronics at the IEEE FLEPS 2024 International Conference on Flexible and Printable Sensors and Systems in Tampere, Finland. The workshop, held alongside three other EU-funded projects, was a part of the larger gathering that brought together experts and enthusiasts in the field of flexible and printable sensors and systems.

The workshop theme centered around the cutting-edge realm of energy-autonomous self-powered wearable electronic devices, spotlighting the dynamic interplay between energy harvesting systems and transformative energy storage solutions, specifically batteries and supercapacitors.

The workshop was inspired by four EU-funded projects—SUPERIOT, SOLiD, GRAPHERGIA, and ARMS—and aimed to provide a comprehensive exploration of sustainable technologies. During the event, six exceptional speakers representing the projects shared their expertise:

- Sam Mousavi presented the captivating SOLiD Project that delves into enhanced energy density batteries via the R2R process and advanced cathode materials, solid polymer electrolytes, and conducting additives. , added depth to our workshop's focus on energy storage innovation while

- Spyros Yannopoulos and Dorela Hoxha provided insights on the GRAPHERGIA project, which aims to develop an innovative method for utilizing graphene-based materials and nanohybrids in energy harvesting and storage devices, particularly in smart textiles and next-generation Li-ion batteries through laser-assisted graphene production.

- Marja Välimäki and Marcos Katz introduced the innovative SUPERIOT project, with its dual-mode optical and radio communications and utilization of printed electronics, sets the stage for a truly adaptable Internet of Things (IoT) system

- Jari Keskinen delved into the intricacies of project ARMS, which aims to amplify supercapacitor energy density through novel materials and fabrication techniques like ALD.

The workshop emphasized the integration of energy storage systems with energy harvesting solutions, particularly showcasing the relevance of the Graphene flagship to the GRAPHERGIA and ARMS projects, which leverage 2D materials in battery and supercapacitor development. By bringing together experts and enthusiasts in the field, the workshop fostered collaborative discussions and explored the future of wearable electronics, highlighting the vital role of sustainable energy solutions.

The workshop was a success, thanks to the insightful contributions of the presenters and the enthusiastic participation of the audience. Twenty-five individuals were present, engaging in thought-provoking discussions and collaborative exchanges that showcased the latest innovations in energy storage, harvesting, and energy-autonomous wearable electronics. Attendees praised the in-depth presentations and interactive sessions, with many highlighting the workshop's innovative approaches as particularly enlightening.

The positive feedback from participants emphasized the workshop's impact in fostering a vibrant exchange of ideas and driving progress in energy technology. The workshop's success is a testament to the power of collaboration and shared knowledge in advancing innovation.