Innovating energy storage: graphene-enhanced micro-flexible and structural supercapacitor electrodes at KTH Royal Institute of Technology

The Printed Electronics group at KTH has extensive experience in developing eco-friendly conductive inks using carbon-based materials, particularly graphene and other 2D materials. These inks are tailored for various manufacturing processes, such as inkjet printing, 3D printing, airbrush spraying, and supersonic spraying, and serve a range of industrial applications, including supercapacitors, thermally conductive coatings for electronics cooling, and conductive wear-resistant coatings for electrification. KTH is also exploring innovative self-charging energy systems that combine energy harvesters (triboelectric nanogenerators) with energy storage devices (microsupercapacitors) to capture and store energy from the environment.

In ARMS, KTH leads Work Package 2 (WP2), focusing on the fabrication of graphene-enabled binder-free electrodes for micro-flexible and structural supercapacitors. The primary responsibility under WP2 is the development of supercapacitor electrodes compatible with atomic layer deposition (ALD) processes in WP3. KTH has been using the bio-derived activated carbon materials and graphene supplied by other partners to formulate proper inks and fabricate graphene-enhanced binder-free carbon electrodes on both flexible substrates and carbon fibres.

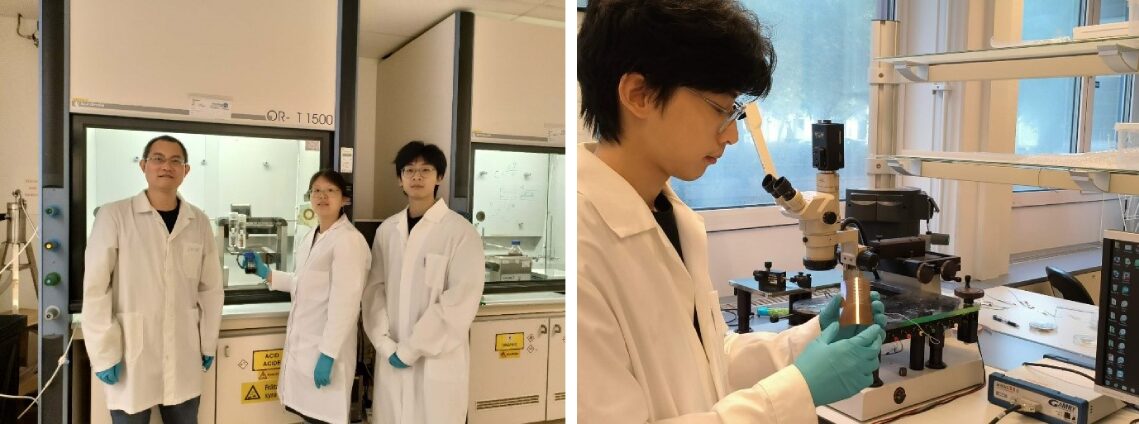

The ARMS project team at KTH is led by Assoc. Prof. Jiantong Li, mainly with the support of Dr. Yingchun Su and PhD student Yujie Fu. Currently, we have developed processes to fabricate binder-free carbon electrodes on flexible (Kapton) substrates and carbon fibers with thermal stability higher than 300 oC. The good thermal stability will provide more flexibility for WP3 in selecting compatible materials for the ALD processes. Based on the feedback from partners, we are developing appropriate processes to improve the adhesion property of the binder-free electrodes.