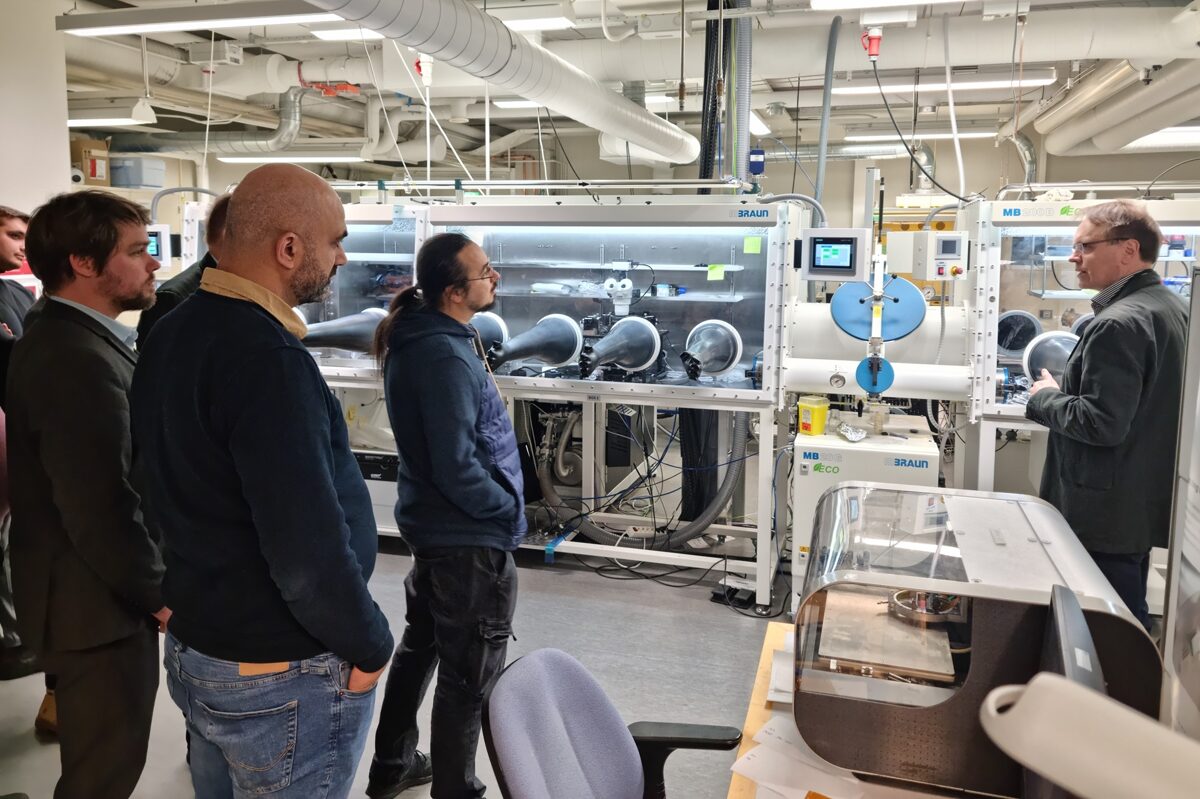

Exploring the future of electronics: project ARMS partners visit the Tampere University’s Laboratory for Future Electronics

In the heart of cutting-edge technological research lies Tampere University’s (TAU) Laboratory for Future Electronics (LFE), a hub of innovation dedicated to unravelling the mysteries and possibilities of future electronic technologies. During the project ARMS kick-off meeting, project partners had an opportunity to visit LFE and delve into LFE research in energy autonomy, sensors, wearable electronics, and hybrid system integration.

Visitors learned about the LFE's spectrum of research themes that cover a broad array of electronic applications:- Flexible/Bendable/Stretchable Electronics: LFE delves into the development of electronics that can seamlessly conform to various shapes, paving the way for flexible and adaptable devices.

- Integration of Printed and Conventional Electronics: With a focus on hybrid systems, LFE explores the synergy between printed components and traditional electronic assembly methods, emphasising scalability and cost-effectiveness.

- Energy Storage and Harvesting: LFE's researchers are at the forefront of investigating technologies related to energy autonomy, exploring innovative solutions for storage and harvesting that could redefine how electronic devices power themselves.

- Printed Thin-Film Circuits and Systems: The laboratory is dedicated to advancing the field of printed electronics, emphasising scalable, low-cost manufacturing methods.

During the visit, project ARMS participants could see the state-of-the-art infrastructure. The laboratory is equipped with cutting-edge tools and machinery that facilitate research. The printing facility houses an impressive array of printers, including inkjet printers, gravure, flexo, rotary screen, and 3D electronics printers. These tools enable the development of electronic components with precision and efficiency. The glove box system, filled with nitrogen, provides an ideal device fabrication and characterisation environment. Integrated tools such as Dimatix inkjet printers, ALD, spin coaters, and vacuum hot plates ensure meticulous control over the production process. There is also electrical characterisation equipment in the LFE: probe stations, semiconductor analysers, potentiostats, and devices for measuring supercapacitors and batteries. These tools play a crucial role in evaluating the performance and efficiency of electronic components. Visitors were also acquainted with material testing equipment for assessing the mechanical properties of functional materials, including testing equipment for ferroelectric and piezoelectric materials.

The laboratory visitors grew assured of TAU LFE's capacity to significantly contribute to advancing environmentally friendly supercapacitors, a key aspect of the ongoing project ARMS.

More information about the laboratory